Uncategorized

Why Hastelloy C276 Is the Best Choice for Harsh Chemical Environments

Validyne Engineering now offers an optional sensor body construction in Hastelloy C276. This greatly improves the corrosion resistance of transducers used in applications where highly oxidizing chemicals are present in the process media. Along with a Teflon-coated sensing diaphragm and wide selection of O-ring materials, the Hastelloy C276 transducer is the most corrosion-resistant transducer ever offered by Validyne Engineering.

Hastelloy C276 is a nickel-chromium-molybdenum alloy that has been proven in over 50 years of service in corrosive environments. According to the data sheet by Haynes International, the manufacturer of Hastelloy C276: “With its high chromium and molybdenum contents, it is able to withstand both oxidizing and non-oxidizing acids and exhibits outstanding resistance to pitting and crevice attack in the presence of chlorides and other halides. Furthermore, it is very resistant to sulfide stress cracking and stress corrosion cracking in sour, oilfield environments.”

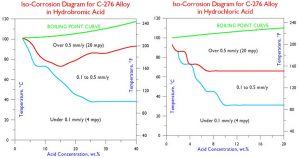

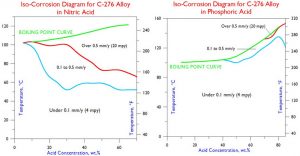

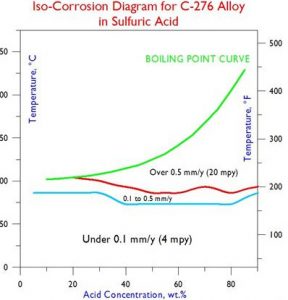

Other Validyne sensor materials include 316 SST, but Hastelloy C276 does much better where strong acids in high concentrations are present. From the Haynes International Data sheet:

“To compare the performance of HASTELLOY® C-276 alloy with that of other materials, it is useful to plot the 0.1 mm/y lines. In the following graphs, the lines for C-276 alloy are compared with those of two popular, austenitic stainless steels (316L and 254SMO), and a lower-molybdenum nickel alloy (625), in hydrochloric and sulfuric acids. At hydrochloric acid concentrations above about 5%, C-276 alloy provides a quantum improvement over the stainless steels and offers much greater resistance to higher concentrations of both acids than alloy 625. The concentration limit of 20% hydrochloric acid is the azeotrope, beyond which high temperature corrosion tests are less reliable.”

The graphs show that Hastelloy C276 survives higher concentrations and higher temperatures of two common acids than does most grades of stainless steel, given the same corrosion rate of 0.1 mm per year.

The addition of Hastelloy C276 as an optional sensor body material will mean greater reliability of pressure transducers in corrosive applications.

Leave a reply

You must be logged in to post a comment.